Maintenance

The proper functioning of production equipment is essential for the productivity of factories and their machines, but also for the quality of their production. To date, there are two types of maintenance which are carried out, depending on the condition of the equipment: corrective maintenance and preventive maintenance.

Corrective maintenance corresponds to all the activities that are carried out following the failure, breakage or proven degradation of industrial machinery. The purpose of corrective maintenance is therefore to restore the structure to its original state, with or without modification, and to check that it is working properly.

Preventive maintenance aims to prevent the risk of failure, breakage or degradation of industrial equipment. This type of maintenance is carried out before a problem is detected. It also aims to minimise maintenance-related costs by servicing the equipment regularly.

There are also a number of other maintenance operations, such as:

- Repair (action following a failure)

- Troubleshooting (temporary action following a breakdown)

- Verification (occurs after a maintenance action)

- Control (checking that the equipment is working properly)

- Adjustment (establishing the correct accuracy for a measuring device)

- Calibration (bringing an instrument back to an optimal level of precision)

- Technical expertise (assessing the condition of an allegedly defective device)

Furthermore, it should be noted that AFNOR identifies 5 levels of maintenance defined according to the complexity of the work to be carried out:

- Level 1: Simple adjustments carried out by the manufacturer or the maintenance service, without dismantling the device. These interventions can be carried out with reference to manual and without the need for any special tools.

- Level 2: Troubleshooting by standard exchange. This is a minor preventive maintenance operation. The intervention can be carried out by an authorised technician or the user of the equipment provided he or she has received appropriate training.

- Level 3: Carrying out a breakdown diagnosis followed by a repair/exchange of a part. These interventions can be carried out by a specialised technician using the tools and maintenance instructions.

- Level 4: Major corrective or preventive maintenance work, not including renovation and reconstruction. These operations are generally carried out by teams with a high level of competence.

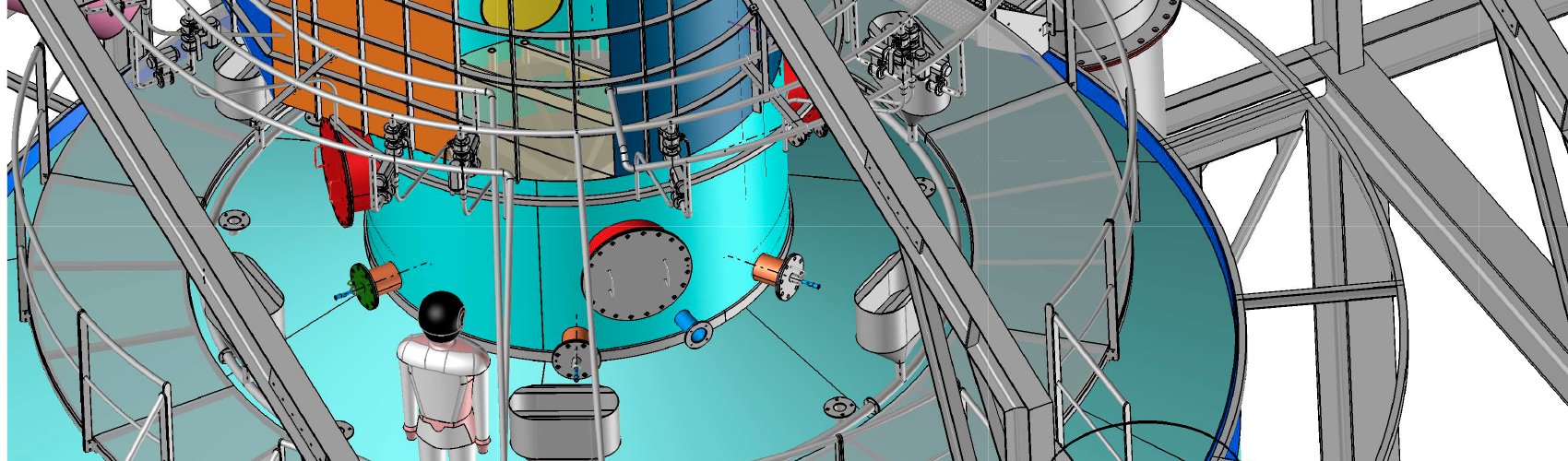

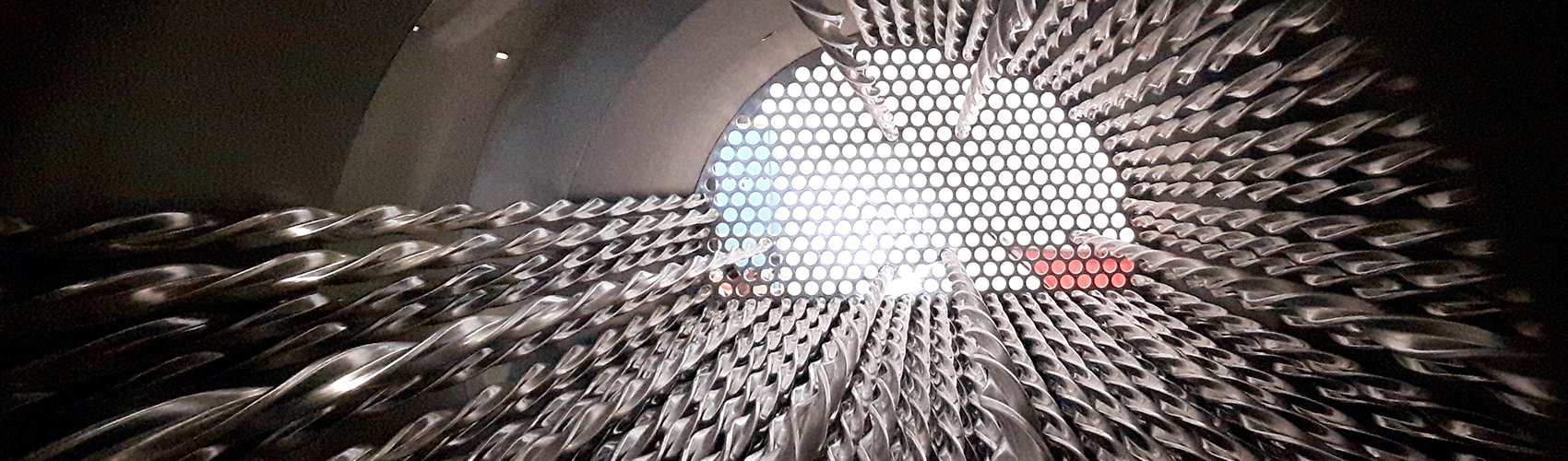

- Level 5: Renovation and reconstruction work. These operations are generally performed by a specialised service provider such as Moscatelli.

At Moscatelli, we place our expertise and know-how at your disposal for all types and levels of maintenance. With nearly 50 years of experience, we offer various services in all areas of metallurgy and industry. For more information about our services, or for a quote, please do not hesitate to contact us by telephone on 04 90 39 67 42.