Distillation

Distillation is a principle used in several sectors of activity, particularly in the pharmaceutical and medical industries. This technique consists of transforming a liquid into vapour by heating it to high temperatures and then condensing this vapour by cooling it in order to collect the new distilled liquid. Distillation is used to purify certain liquids such as water or essential oils in aromatherapy.

PHARMACEUTICAL DISTILLATION OF WATER:

Purified water is the element most used in the pharmaceutical sector, particularly because of its presence in most medicines produced. There are several types of pharmaceutical water, classified according to quality. Depending on the distillation method used, the water has its own microbial and chemical purity, which will make it possible to define its use. Free of endotoxins (which can cause inflammation), distilled water is of great microbiological and physico-chemical purity. Among the various water distillation techniques most commonly used are ion exchange, reverse osmosis and ultrafiltration. UV treatment can also be used in order to make the water more microbiologically safe.

DISTILLATION OF ESSENTIAL OILS FOR MEDICINE:

Essential oils found on the market or used in medicine are extracted from plants by steam distillation. Vapodistillation or hydrodistillation are the two methods used to distil the active ingredients of a plant in aromatherapy or phytotherapy. Several means of administration exist for distilled essential oils. The two main ones are oral or dermal, but it is also possible to administer the distilled essential oils by diffusion or inhalation.

DISTILLATION TECHNIQUES:

Several different distillation techniques can be used, their appropriateness depends on the products to be distilled and the result that one wishes to obtain. Among the different distillation techniques there are :

Distillation with steam distillation (distillation of aqueous solutions with a water-immiscible organic compound)

Fractional distillation (separating two liquids with different boiling temperatures)

Molecular distillation (fractional distillation under high vacuum)

Distillation under reduced pressure (to reduce the risk of degradation of the elements by heating)

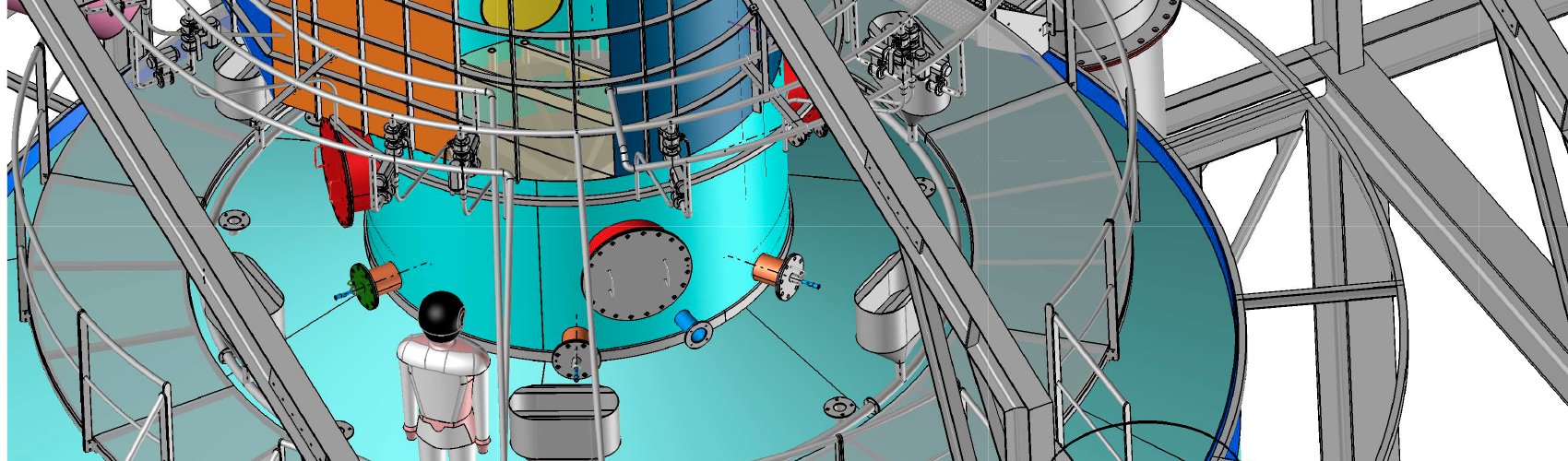

Moscatelli offers its expertise in the elaboration, construction and installation of distillation equipment for your company. Depending on your project and your needs, our teams will design and build the appropriate equipment to suit your requirements.

MOSCATELLI PROVIDES YOU WITH VARIOUS SERVICES IN THE DISTILLATION SECTOR:

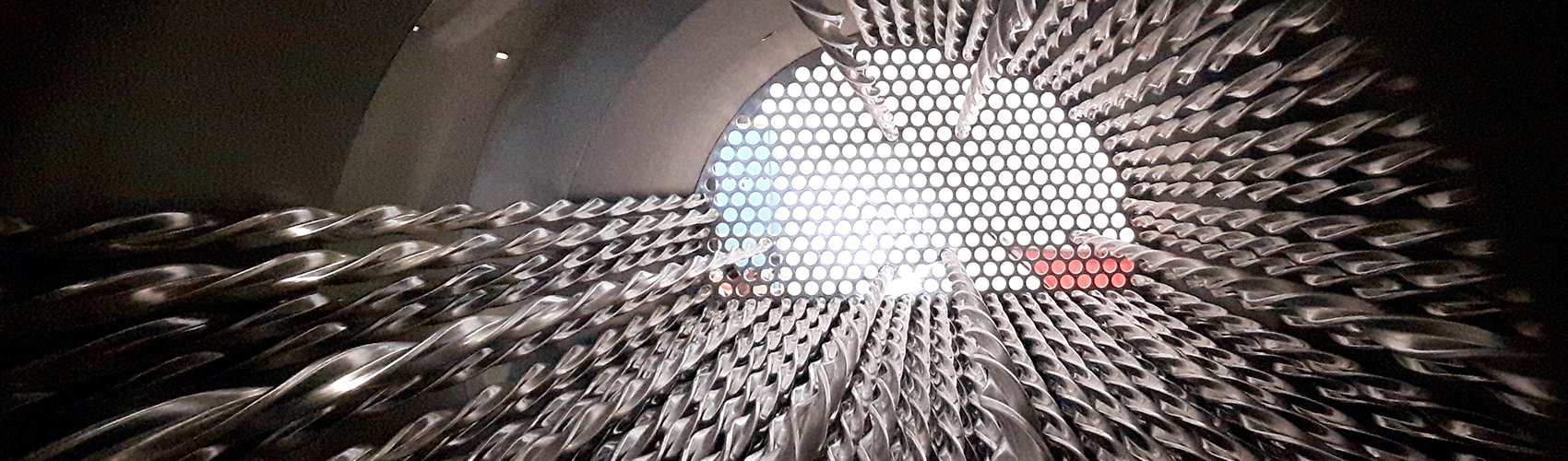

For nearly 50 years we have been manufacturing metallurgical materials and equipment in the distillation sector. We build all types of distillation equipment, tailored to the needs and expectations of our clients. With our experience and precision know-how, we master the various trades of metallurgy: corrugation, mechanics, ventilation, piping... in order to offer you services that meet the strictest quality criteria.

In addition, as industrial engineers we provide various services such as project management and monitoring, equipment design and modelling or technical activities such as heat exchange calculations or the requalification of pressure vessels.

For more information on our services, please do not hesitate to contact us by calling 04 90 39 67 42.